1958 Cadillac Sedan DeVille

Winning the 2022 Car of the Year competition may have seemed like a foregone conclusion to many (have you seen this car?!). However, creating such a masterpiece of restoration was many years in the making for owner Steve Sullivan and a voyage of discovery too, as editor Ben Klemenzson found out…

Words: Ben Klemenzson

Photography: Jonathan Fleetwood

Motordom's Masterpiece

Attention to detail’, ‘points win prizes’… these are just a couple of the aphorisms which could apply to Steve Sullivan’s approach to restoring the 1958 Cadillac Sedan DeVille pictured on these pages. As we sit in a pub having lunch, we flick through the pictures he’s meticulously taken to record every stage of the car’s resurrection into what he was ultimately aiming for: a brand-new Cadillac, just as it would have appeared when it rolled off the production line or into the showroom in 1958. In fact, not even that, better than any new Cadillac of the time. “You’re trying to create something better, rather than something they couldn’t or didn’t have time to make.” He explains: “I think the guys that designed this car would have wanted it to be like this.” Controversial? Maybe, but I’d prefer ‘refreshing’. Our hobby, as we know, is dominated by an orthodoxy that believes even evidence of cost-cutting and poor quality should be replicated in restorations to make them authentic. I’m thinking of things like overspray on award-winning Mopars “because that’s how they did it in the factory”…

I explain that it’s doubtful we’ll be able to use all of the 100+ images he’s provided me with in the feature and he responds that he actually has more than 3000. Quite. That may even explain why the restoration took so long (five years in total) as it was all being so painstakingly photographed! What about the car itself? Steve explains he got it off eBay and that it had been brought into the UK by a British buyer who had intended to use it for weddings, but when it arrived had been put off by the multiple issues it was seemingly suffering from (spongy brakes, bearing noises and oil leaks being the least of them) and so he promptly moved it on. The car came from New York and was sold new by the now long-defunct Don Scott dealership, but other than this information, there’s virtually no history of the car’s life before it came to these shores. What is for sure is that it must have been garaged and/or possibly not used in the winters, as what little corrosion there was seemed to be limited to the usual traps behind the wheels on the rear quarters and front wheel openings. So, what attracted him to this car in particular and American cars in general? Steve explains that he wanted an unmolested example, one that hadn’t been restored or modified in any way.

Likewise, the Sedan DeVille had all the bells and whistles he was after, including power windows, seats and things like the self-seeking radio. “But why a ’58?” I ask him and “why a Sedan DeVille rather than an Eldorado or even a Brougham from the same year?” (we all know about those ‘parts car’ jokes about four-door cars…). Steve explains he just likes the look of them and thinks four-door cars are underrated on the classic American car scene: “I think a Cadillac just looks better with four doors… but that’s just my opinion,” he says. Again, a refreshing outlook. As for American cars, he’d always loved the optimism of the era they represented and told of a visit to the US to visit an aunt where he spent most of his time photographing cars, something probably many readers can relate to.

“THE BEST WAY FOR ME TO GET INFORMATION IS IF SOMEONE’S ADVERTISING AN UNRESTORED CAR IN THE STATES ON EBAY USING GOOD QUALITY PICTURES… IT’S AMAZING WHAT YOU CAN FIND OUT.”

Voyage of discovery

What’s important to understand about this car and its restoration is that despite having his own classic car restoration business in Greater Manchester, this car, and the work done on it, was for himself alone and not with a view to selling the car on afterwards for a profit. That in itself would have been a challenge, as the sheer cost of the number of man hours (estimated at 3000) that have gone into the restoration of the Cadillac far exceed what one would imagine he would ever be able to recoup for it, (although, as Steven says: “There is always a customer for the very best”). It’s rare to come across a car where the owner has restored it purely to create a car for his own pleasure. Steve opines he actually enjoyed restoring the car and learning how Cadillac put them together, although even that has been a mixed experience.

Cadillac may have trumpeted words like ‘craftsmanship’ and ‘quality’, but let’s face it, these cars were being churned out of the factory in Detroit on an industrial scale at a remarkable rate on a production line probably no different from those producing washing machines or televisions. They were a consumable product and as such the bean counters would always be looking for ways to cut costs or speed up production. For Cadillac, being a luxury product meant that the smoke and mirrors of marketing the brand and advertising it were what gave Cadillac – especially in the Fifties and Sixties – that ‘je ne sais quoi’… or as the TV adverts of the time proclaimed: ‘Motordom’s Masterpiece’. In some ways, you could consider them the Apple product of the time. Great design and marketing, put together in sweat shops– not in China, but Detroit.

Also, being a luxury car meant Cadillac’s primary concern was for the initial buyer; it wasn’t really bothered about what happened to the cars further down the food chain, say 10 or 15 years later when it was probably rattling around some impoverished slum neighbourhood of any big American city of the time. That probably explains anomalies like the use of loft insulation soundproofing-type material in the bulkhead cavities, which although featuring a drain hole (which must almost inevitably block up!) would cause water to be held close to the metal and rot. Great for the early owners as it would enhance the car’s noise-cancelling credentials, but not so great in the latter years when it would encourage corrosion. Steve discovered things like this throughout the car, even on something like the speedometer cluster, which when dismantled featured cardboard tubes (little ‘bog rolls’ is how he described them) to funnel the light from dashboard bulbs to the coloured dashboard warning lenses.

There can’t be any facet on the vehicle that he hasn’t had a hand in dismantling, restoring and putting back together. All the glass was replaced, with the etchings reproduced and put on them by Steve himself. The grille was not up to the standard Steve wanted, so was dismantled and the ‘bullets’ polished and machined, while new cross-sections to which they were attached were fabricated using new aluminium and a water jet cutter. What’s remarkable about the work Steve has carried out on this car is there is so much good stuff that can’t even be seen; the window regulators behind the door cards, apart from being refurbished, also had the factory stencils on them replicated.

Likewise, stencil markings on the chassis rails underneath the car (in fact the whole of the underneath is like a brand-new car) are done upside down as the chassis were stamped when they were upside down at the factory.

Second time lucky

This isn’t Steve’s first American restoration; you may remember his Ford Thunderbird that featured in the Car of the Year competition back in 2017. So, what is a classic American car like to restore compared to the British and European classics that tend to be the bread and butter of Steve’s business? “There’s a lot more of it, plus there are so many separate parts to line up; whereas a modern car may have a chassis with a specific mounting hole, the American will have a big oval hole with shims (for adjustment),” explains Steve.

Of course, it’s not always possible to totally replicate everything as it was done in the late Fifties on a project like this, as quite simply some of the materials used are no longer available, or legal even: things like asbestos brake pads, or the red lead undercoating that was used extensively on the car as an early rustproofing under the paint and on the underside of the car. Nevertheless, Steve has created his own formula, which replicates the appearance, at least, of the red lead. What has been interesting for Steve has been the research that he’s had to undertake as part of the car’s resurrection. “The best way for me to get information is if someone’s advertising an unrestored car in the States on eBay using good quality pictures… it’s amazing what you can find out.”

But back to the restoration: Steve stripped the car down, took the body of the chassis and sent it to Lancashire Motor Bodies ( lancashiremotorbodies.co.uk) of Eccles where it was bare-metalled and repairs, including lead loading, were made to areas such as the passenger side rear wing which had been badly repaired, presumably after some minor accident, perhaps back in the Sixties. Meanwhile the front wings were sent to SPL (www.surfaceprocessing. co.uk) in Dudley, West Midlands for dipping to get the hard-to-shift layers of underseal off them. Steve even undertook the drive to Sweden with his dashboard pad to have it refurbished by RD Autoline (www.autoline.se), the only company in Europe specialising in refurbishing American dashpads. The seats all benefited from new material done as per the original from SMS Auto Fabrics (smsautofabrics.com ) of Canby, Oregon and the leather was restored by a business in Knutsford, Cheshire.

Interestingly Steve elected to retain the original wiring loom and only replaced bits in the engine bay that had become fried over the years.

The restoration took five years in total and the Cadillac made its debut at the Rally of the Giants at Blenheim Palace in the summer of 2021, where it picked up Best Cadillac. It later picked up Best Fifties at the 2022 European Cadillac La Salle Club event in Freiburg, Germany, as well as best in class at the London Concours show. It’s been quite the voyage of discovery for Steve, returning this Cadillac to a condition that can only be described as better than new and it was for that reason it was crowned Kingstown Shipping’s Car of the Year at the Finals at last year’s Classic Motor Show. Could there be another show-stopping car in the pipeline for Steve? He nods his head and mulls over the possibility of a late Fifties Dodge or DeSoto. Now that would be something to behold!

Headliner was one area retained as completely original and unrestored. Masked-off original dash signature preserved. Immaculately restored grille. The perfect view.

Late Great ’58

Cadillac’s ’57 and ’58 year models were the cars that bridged the bulbous, bulky styling of the ’50 to ’56 model years to the longer, lower, svelte designs of the ’59/’60s. The ’57 was an all-new model, boasting an X-frame that in removing the side chassis rails enabled it to be dropped three inches lower than the previous year’s model. While the ’57s retained the gull-wing front bumper and introduced a one-year-only rear slanted fin (dropped as it supposedly made the car look shorter), it was all change again for 1958. Now, there were twin headlamps up front and that egg-crate grille, as well as new, rear-facing, more dramatic tail fins, aimed at making the car look longer.

GM’s other ’58 models wore trowels of chrome and ornamentation down the side and had Harley Earl had his way, Cadillac would have suffered the same fate. Studio design assistant Dave Holls remembers thinking: “Oh my God, they’re going to release the 1958 Cadillac looking like that?” – however, in a potentially career-ending move, studio chief Ed Glowacke removed these excesses at the last minute. Had he not done so, we might not consider the ’58 Cadillacs to be the best looking of GM’s 1958 range. Interestingly Earl deliberately set out to make the ’58 Chevy look like a baby Cadillac and it was something that he’d done similarly in 1932, when Chevrolets that year looked like scaled-down Cadillacs.

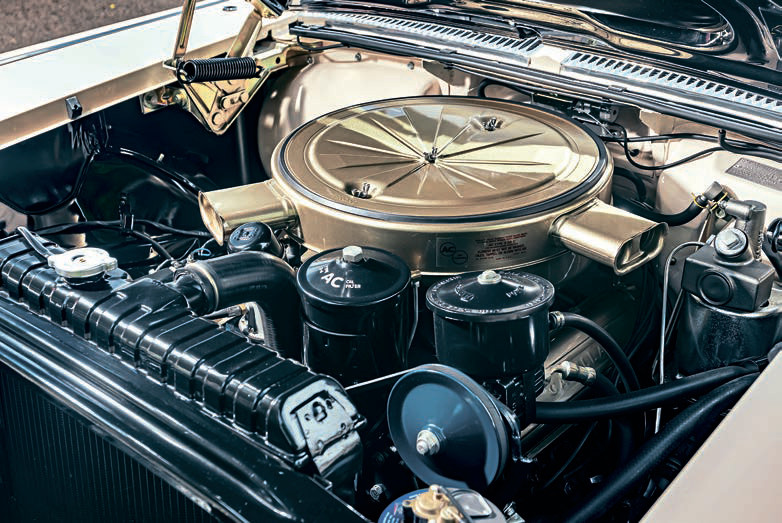

Power came from a 310bhp 365cu in V8 with 10.25:1 compression, with a triple two-barrel carb option (as fitted on Steve’s car) that took power up to 335bhp. The big story for ’58 Cadillacs was the option of air suspension, a $215 option that was fitted to 14% of production that year.

The system proved problematic and was abandoned just a few years later. With Packard in its death throes the luxury market was dominated by Cadillac in 1958, selling 121,474 cars in total, almost four times as many as Lincoln, who sold 29,684 that year (including Continental Mark IIs) and poor old Chrysler who sold half as many again, with only 16,133 Imperials finding buyers.

Selling the dream, 1958 style.

Trunk area is as pristine as the rest of the car.

Stunning brocade and leather interior came from SMS Fabrics, Oregon.

Four-window controls and remote mirror. Back seat appears as if unused.

Original-style battery. Glass and paper fuel filter. Optional tri-carb set-up. 310bhp 365cu in V8. Original-style owner’s ID card.

Discreet, but clever… … fuel filler.

Restoration

- Steve’s desire to get his hands on a vehicle which hadn’t been modified or restored meant he had to do quite a lot of work on it; everything from bodywork, to mechanicals and interior trim.

- Strip-down on Cadillac commenced in 2016 and was a long process, five years from start to finish.

- Some of the worst corrosion was behind the front wings, only visible when removed.

- Taking the body off the chassis revealed the shims used for adjusting the fit.

- Body was put on castors to move about easily while chassis was worked on.

- Bulkhead covers with corrosion caused from water being trapped by insulation.

- Front wings were sent to SPL to be dipped, as layers of underseal were proving difficult to shift.

- Boot lid being stripped reveals the red lead primer used underneath the paint.

- Rear quarter panel was repaired using lead loading, expertly done by Lancashire Motor Bodies.

- Rear quarter after repair in primer on a dolly getting ready for paint.

- X-frame was cleaned up and painted, with all ancillaries restored.

- The famous body-drop…

- This is what a body-off restoration looks like!

- Check out this corroded radiator frame lower mounting. Most people would just chuck it away and use a new one…

- Fully restored mechanism, complete with stencil part number which can’t be seen.

- Dismantled speedometer with cardboard tubes that guide to the lenses in the housing.

- Carburettors were stripped, vapour blasted and then ultrasonically cleaned and rebuilt by Steve himself.

- ...Not Steve, he cleaned it up, machined it and polished it until it was as good as new!

- Escutcheons were difficult to restore and eventually recreated on a belt sander.

- Door cards are incredibly complex with fabric, vinyl and stampings, but ultimately just with a card backing.

- Rear of speedo all cleaned up. It included a stamping showing an assembly date of February 27, 1958.

- Dropping the dash off at RD Autoline in Sweden, the only company in Europe which refurbishes American dashpads.

- Power window assembly prior to dismantling and restoration.

- Leather was restored and recoloured by Leathercare of Knutsford, Cheshire.

- Engine was refreshed and repainted, all new gaskets were fitted to curtail the oil leaks.

- One of the aluminium bullets prior to polishing. Note the corrosion and pitting.

- Grille almost reassembled using clips behind the bullets and grille. Grille alone took six months to do.

- Above right: Grille was attached to a plywood frame and then lifted into place using two trolley jacks at either end.

- Far right: Flexible metal exhaust tubing covers the exhaust pipe under the car.

- Right: Upside down stencilling on the chassis rails.

- Refurbished power aerial. This was one of the many things not working when Steve got the car.

- The grille ‘bullets’ were put on a lathe and polished. There were about 80 in total.

- Up behind the headlamps, in the front wing red lead primer was used extensively.

- Cross-pieces that the bullets interconnect with were fabricated from aluminium using a water jet cutter.

- Rear axle was sand blasted (although sealed so no sand could get in!) and pitted areas were attended to.

- After being polished and anodised, Steve started to build them up using cable ties to hold them in place…

- Threads on the wheels on the other side have ‘Ls’ to indicate their thread is counter.