Hydrogen 2023 BMW X5 G05 enters production

BMW is continuing to test hydrogen as an option for electric drivetrains,now the iX5 Hydrogen has entered small series production.

BMW is continuing its exploration of hydrogen technology with the small series production of the iX5 Hydrogen. Fuel cell system production at the company’s competence centre for hydrogen in Munich got underway recently, the 2023 BMW iX5 Hydrogen G05 cars produced will enter service around the world from the end of this year for test and demonstration purposes. BMW has been exploring hydrogen technology since 2013, and prides itself on playing a pioneering role in its use. For many industry insiders, fuel cell technology makes the most amount of sense for the future of mobility. And, since the BMW 5 Series GT Hydrogen Cell of 2015, fuel cell technology has been steadily refined.

“As a versatile energy source, hydrogen has a key role to play on the road to climate neutrality. And it will also gain substantially in importance as far as personal mobility is concerned. We think hydrogen-powered vehicles are ideally placed technologically to fit alongside battery-electric vehicles and complete the electric mobility picture, said Oliver Zipse, Chairman of the Board of Management of BMW AG. “By commencing small-scale production of fuel cells today, we are demonstrating the technical maturity of this type of drive system and underscoring its potential for the future.

“Our many years of research and development work have enabled us to get the very most out of hydrogen technology,” added Frank Weber, Member of the Board of Management of BMW AG, Development. “We have managed to more than double the fuel cell’s continuous output in the second- generation fuel cell in the iX5 Hydrogen, while weight and size have both decreased drastically.”

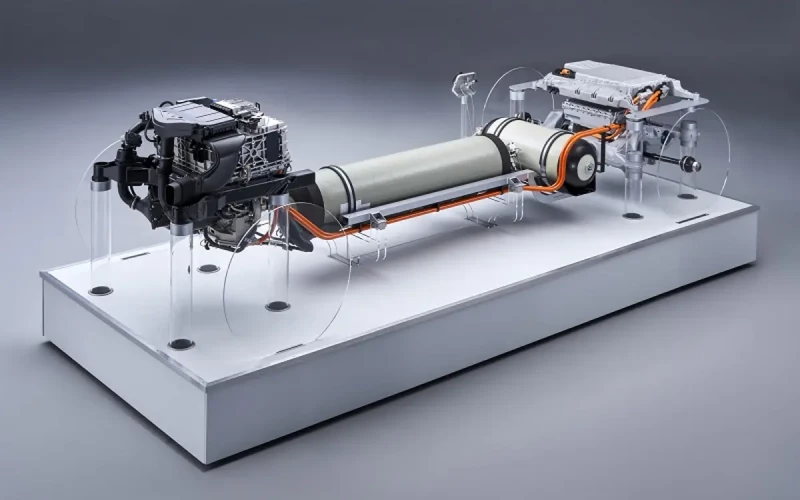

The technology in the iX5 Hydrogen generates a high continuous output of 125kW/170hp. It teams-up with an electric motor and a high-performance battery developed specially for the vehicle, this enables the powertrain to deliver 275kW/374hp. The system comprises two hydrogen tanks, fuel cell and an electric motor, this is integrated into the existing X5 platform enabling the small production run. The iX5 Hydrogen already underwent extreme weather testing in icy Sweden at the start of this year.

Now, you might be wondering how it all works. In essence a chemical reaction takes place in the fuel cell between hydrogen from the tanks and oxygen from the air. Maintaining a steady supply of both elements to the fire cell’s membrane is of crucial importance for drive system efficiency. In addition to the technological equivalents of features found on combustion engines, such as charge air coolers, air filters, control units and sensors, BMW has developed special hydrogen components for its new fuel cell system. These include the high-speed compressor with turbine and high-voltage coolant pump, for instance.

BMW sources the individual fuel cells themselves from Toyota. The two companies have enjoyed a partnership since 2013, collaborating on fuel cell drive system developments. Fuel cell systems are manufactured in two main steps. The individual fuel cells are first assembled into a fuel cell stack. The next step involves fitting all the other components to produce a complete fuel cell system.

Stacking of the fuel cells is a fully automated process. Once the individual components have been inspected for any damage, the stack is compressed by machine with a force of five tonnes and placed in a housing. The stack housing is manufactured in the light metal foundry at BMW's Plant Landshut using a sand casting technique. For this, molten aluminium is poured into a mould made from compacted sand mixed with resin in a process specially designed for this latest small-series vehicle. The pressure plate, which delivers hydrogen and oxygen to the fuel cell stack, is made from cast plastic parts and light-alloy castings, also from the Landshut plant. The pressure plate forms a gas-tight and water- tight seal around the stack housing.

Final assembly of the fuel cell stacks includes a voltage test along with extensive testing of the chemical reaction within the cells. Finally, all of the different components are fitted together in the assembly area to produce the complete system. During this system assembly stage, further components are fitted, such as the compressor, the anode and cathode, the high-voltage coolant pump and the wiring harness. Whether or not BMW will roll out this technology on a larger scale remains to be seen.