Living with the Jaguar XJ Series 3

V12 thirst aside, the last of the traditional XJs can be a surprisingly practical classic but don’t expect an easy ride.

WORDS PAUL WAGER

LIVING WITH THE SERIES 3 JAGUAR XJ

An up-together Series 3 XJ can be a delightful prospect, but a down-at-heel example can quickly drain you of funds and enthusiasm. Here’s how to stay on the right side.

Today the last of the ‘Series’ XJs is an intriguing proposition, combining the appeal of the classics like the Mk2 with the practicality of the later cars from the XJ40 era and beyond. A good one can be an enjoyable way to travel with enough pace to cut it in modern traffic and refinement to equal many modern executive offerings… but a down-at-heel example can prove ruinous when body rot and engine problems start to gang up on you. Whether you’re already an owner or looking to take the plunge, here’s what you need to know in order to make your Series 3 experience as pleasurable as possible.

HISTORY

Sir William Lyons has been given much credit for Jaguar’s design direction and the XJ was no exception, but it was Pininfarina which took the Lyons original and managed to improve it, the brief being to extend the life of the original design for long enough for the XJ40 development programme to reach conclusion.

The work was incredibly subtle but very significant and managed the make the car look longer and sleeker whilst actually raising the rear roofline to create more interior space. An enlarged glass area reinforced the sense of rooominess and the interior was suitably modernised too.

Engine options were carried over from the Series 2, with the 4.2 gaining fuel injection and both six-cylinder cars now offered with the LT77 five-speed manual box as an option.

Quality however, was still a major issue but in April 1980 John Egan arrived at Browns Lane as the new Chief Executive of Jaguar. Ironically, he had to pass through a picket line on his first day at the office, but quickly got to grips with the many issues crippling the firm. His most significant achievements was to bring the Castle Bromwich plant under Jaguar control, in order to improve the quality of the finished bodyshells being supplied to the assembly plant at Browns Lane. Alongside this, Egan also established a system making third-party component suppliers take responsibility for the quality of their products and slowly but surely the quality of the cars began to improve. The Series 3 ended up being the longest-lived of all the XJ generations, with the car lasting in production until 1992, living on as a special order model to satisfy customers who were waiting for the V12 to be made available in the XJ40.

WHAT TO WATCH

BODYWORK

An XJ does many things very well but its chief talent is dissolving in the British winter, not helped by British Leyland’s legendarily patchy quality control. Once upon a time, a rotten example was easy to spot but these days the remaining cars are the presentable-looking ones, so you need to check even more carefully to see what’s hiding in wait behind shiny paintwork. The front wings are a common culprit and with panels no longer available it really pays to keep an eye on them: there’s a dirt trap built into the front end of the sill. If the steel splash panels which are supposed to act as arch liners are missing, it encourages the wing to rot from the inside, while the return lips of the arches are another common problem, so it really pays to get the hose in there and get all the dirt out at car wash time.

Another typical Jaguar issue which wasn’t licked even in the X300 era, is the front and rear scuttles which can be expensive to repair properly. If you see bubbling around either the front or rear screen, start saving for the work which involves removing the glass to do a proper job. Bubbling around the sunroof – whether factory original or ’80s aftermarket pop-up – can mean a similar bill.

Even if the wings and outer sills look solid, it pays to keep a watching eye underneath as structural corrosion can get expensive: keep an eye on the mounting area for the rear radius arms and the suspension subframe, as well as the ‘chassis’ box sections. Lift the carpet inside to keep an eye on the inner sills and the crucial seatbelt mounting points. At the front end, the crossmember is a safety-critical part and although it was powder coated from new, the passage of time can see water seeping in where the coating is cracked, with predictable consequences.

Elsewhere, blocked drains can quickly see the doors rot from the inside along the lower edge as well as the inside trims getting ruined, so poke them out every so often if you have pristine doors. The boot floor and spare wheel well are also common rot spots and since they’re out of sight and out of mind, it can develop to alarming levels before it’s discovered. At least repairs here don’t have to look perfect though.

Parts supply for these cars changes all the time and has actually improved of late: at the time of writing front wings were once again available at £350 each but rear wings and roof skin are NLA, as is the boot lid. Don’t despair though: although complete panels may not be available off the shelf, most of the Jaguar parts specialists can supply all the repair panels you’re likely to need – you can even build up a complete front wing in this way.

BRAKES

At the front end, the system is pretty conventional, using four-pot calipers which can be replaced at reasonable cost if they start to seize or drag. At the rear, things are more involved on account of the inboard rear calipers, which makes access rather more difficult. It’s worth getting under there and checking for leaky differential seals which can contaminate the brake pads. The handbrake uses a separate mechanism and with most of these cars being automatic, it doesn’t get used very often. Combined with the heat from the axle and exhausts, this means the mechanism can tend to seize up to the point where it won’t satisfy the MoT tester. Clearly then, it pays to cycle the handbrake every so often. The same heat can also mean the brake flexi hoses have a short life and can often collapse internally without being obviously damaged, the result being that the restricted flow tends to lock the brakes on. Changing the discs and pads is a job best done with the entire rear subframe lowered, so it’s sensible to try and schedule it in at the same time as anything else which requires subframe removal.

SUSPENSION

As with any classic Jaguar, worn front subframe mounts can cause erratic handling and movement which can be felt when coming to a stop. Decaying upper front wishbone bushes can make the steering feel imprecise but many owners may not notice the gradual deterioration. It’s a DIY job to replace them and will improve the driving experience no end. On the subject of steering, keep a regular eye out for power steering fluid leaks; repair kits for leaking racks are available. At the rear, worn radius arm mounts can cause a clonking over low-speed bumps and contribute to a generally soggy feel to the car, as can worn propshaft and half shafts.

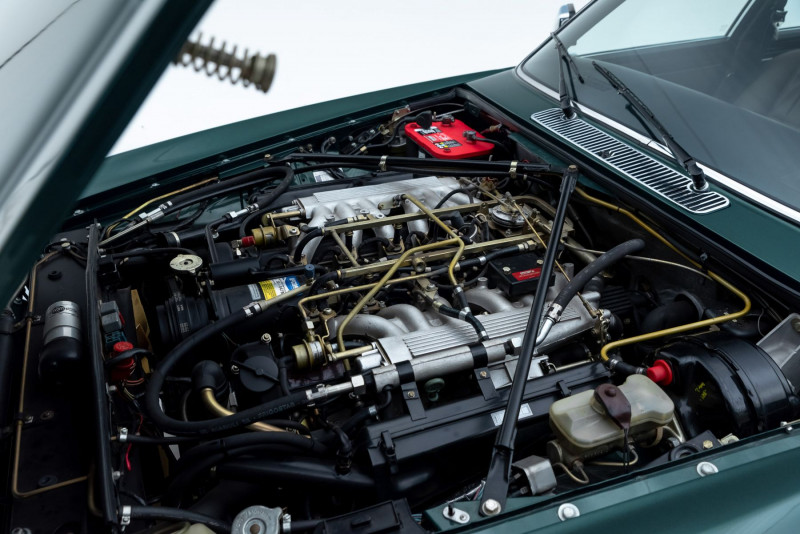

ENGINE

Buying guides will often tell you the XK engine is bulletproof but although it’s a generally robust unit, it does need to be maintained properly. This is especially true of the 4.2 unit: to arrive at the 4.2-litre capacity, Jaguar had to bore out the original XK design significantly and to retain coolant flow between the cylinders the blocks used on the Series 3 cars feature a slot machined into the gap between the bores. As a result, the metal in this area is perilously thin and overheating it can cause it to crack. An engine damaged in this way can be repaired by boring it oversize and fitting a ‘top hat’ liner, but it’s not a cheap exercise. Clearly, the best way of avoiding big bills is to keep on top of maintenance and be alert for any fluid leaks… although oil drips from front and rear crank seals are pretty common, especially on little-used cars where the seals can tend to harden.

On all engines the anti-corrosive properties of correct coolant are essential to avoid internal furring up, so check its concentration with a simple handheld tester or drain and refill if you’re unsure. Be alert for fluid stains along the line of the head gasket area too. A rattle from the front of the engine is likely to be the timing chain assembly, generally caused by worn tensioners. It can be tolerated to a certain extent but leaving it too long runs the risk of the chain snapping. It’s not a particularly difficult job but the amount of dismantling required to get the front cover off can create a big labour bill. The V12 is similarly reliable if it’s looked after, but many owners skimp on things like plug changes owing to the tricky access, with misfires on one or more cylinders often going unnoticed owing to the engine’s innate smoothness.

Don’t panic if the dashboard gauge shows an alarmingly low oil pressure especially on the V12 – the gauge is notoriously inaccurate and in any case just 10-12psi at idle is acceptable, while the figure for the six-cylinder is 20psi.

TRANSMISSION

Both the BorgWarner automatic in the six-cylinder cars and the GM unit in the V12 are reliable, with problems usually obvious and sudden failure uncommon. The inner workings of an automatic box may be voodoo black magic to most of us, but there’s still scope for preventative maintenance: check the fluid using the long dipstick at the rear of the engine bay and assess its condition and level. If in doubt, changing the fluid can massively extend the life of the unit. Noise from the gearbox area may be less of a worry than you think: the sprung central mount is prone to collapsing and replacement can make a big difference to the car’s refinement.

INTERIOR

A shabby interior can really spoil the ownership experience of these cars but with a little ingenuity and effort it can be easy to revive even the most down-at-heel cabin.

The cloth seats standard in the basic XJ6 will be the hardest to improve, with the easiest fix for damaged covers being to simply replace them with leather items. If they’re simply grimy though, renting or buying a carpet/upholstery cleaning machine can be worthwhile – you’ll be amazed at the transformation and the filthy water you’re left with. The leather seats offer more scope for repair, with companies like Gliptone and Furniture Clinic offering colour-matched dyes which can be used to touch up scuffed areas. We’ve surprised ourselves in the past by how much can be achieved using specialist flexible fillers to repair cuts, while spraying the entire seat can transform it. The wooden veneer really hates a damp environment, so storing the car with the windows open in a well ventilated garage is a smart move to prevent the lacquer deteriorating in the first place.

If it’s too late then in theory it’s a specialist job to repair, but with patience a keen DIYer can achieve respectable results by sanding, lacquering and polishing the pieces. Just remember to apply multiple coats of lacquer and to use a proper variable-speed sander/polisher rather than a cheap high-speed ‘car polisher’ or angle grinder which spins too fast for the job. Naturally the headlining will droop over time as it does in pretty much every Jaguar ever made and most owners simply pin it in place for as long as possible, although this merely postpones the inevitable.

When you can’t put off replacement any longer, your choices are either to remove, scrape clean and retrim the original part or buy a ready-trimmed fibreglass board. Both are DIY options, but the fibreglass board can be bent just enough to install through the door aperture without removing front or rear screen. On the subject of the inside, the carpet and the insulation under it is so thick in these cars that it can often conceal dampness from leaking screen rubber or bulkhead. It pays to feel underneath the footwell carpets every so often to keep an eye on things before the interior starts to smell damp.

TECHNICAL SPECS

- MODEL XJ6 3.4 / XJ6 4.2 / XJ12

- ENGINE 3,442cc straight six / 4,235cc straight six / 5,343cc V12

- MAX POWER 161bhp / 205bhp / 285bhp

- MAX TORQUE 189lb ft / 231lb ft / 294lb ft

- TOP SPEED 112.9mph / 122mph / 140mph

- ACCELERATION 0-62MPH 11.2secs / 9.6secs / 7.6secs