Extremely green 275bhp Ford Fiesta Mk8 daily driver

Lean, mean, and very green, this Mk6 Fiesta might look a little sickly, but the only discharge you have to look out for might be some flames coming from the exhaust, courtesy of the turbo’d Honda K24 under the bonnet…

Words ELIZABETH DE LATOUR

Photos ADE BRANNAN

MK8 FIESTA ST-2 Extremely green 275bhp Mk8 daily driver.

Lost kids pick their noses and like to play with their bogies, that’s a simple fact, but most grow out of that phase. Reed Onli, however, has clearly not grown out of it, though the green thing he’s playing with these days is his delightfully named ‘Snotrocket’ Mk6 Fiesta Zetec-S Celebration Edition. And while it might have mucusy connotations, it’s certainly no snotter…

“I’ve been modifying cars for almost three decades, starting with a Ford Fiesta XR2 back in 1995,” Reed tells us, so it’s not that surprising to see him in another Fiesta, and his love of boost goes back a fair way too. “Since 2005, I’ve had a big interest in turbocharging and engine calibration work, and have experience with a variety of OEM and standalone engine control units. I was very fortunate to be mentored by the late ex-Ford Motorsport engineer and Cosworth guru, Ahmed Bayjoo, who I consider to be one of the most influential people in my life,” he adds. Clearly, Reed is a bit handy when it comes to cars; “I’m a keen driver on street and track, and focus on improving my own driving ability, and it’s important to me that the cars I build are fast in both the bends as well as the straights,” he continues, and it’s his passion for the track that fuelled this purchase.

“It was an impulse buy, really; I wanted to build a new track car, and while these limited editions are pretty rare, I always wanted to do something with one,” grins Reed. “I’ve always loved the limited-edition Fiestas such as this Celebration (also the yellow/red anniversary editions), but green is my favourite colour. It’s cheap to buy, lightweight, and ideal for a track car,” he enthuses. “I bought the car about five years ago on Auto Trader. It had been recently painted due to some light vandalism, I suspect, and was completely standard and a good base to convert into a track toy. I’m a member of the ‘Ford’s The Only Way’ club, and I needed a Ford to attend the club’s stand at various events, as well as being blasted around the track! The intent was to build a dedicated track toy that handles excellently and has fantastic driveability with perfect engine control and flexibility,” and it’s safe to say he’s ticked all those boxes and then some.

While this Fiesta might have been an impulse purchase, for Reed it was the chance to really commit to a car. “I don’t generally keep project cars for very long, usually a year or two maximum,” he explains. “I wanted to change that, so the intention for this project was to keep it simple, use it to the maximum enjoyment, and make small iterative changes over many years to keep the interest up, without breaking the bank or motivation and so, work began on ‘Phase 1’ of the build.

“Soon after I picked the car up, I stripped the interior and my friends at Cosworth-experts Grove Garage installed the brakes and suspension. This included a bunch of refurbished and powder-coated parts, with polybushes in certain places. Around this time, I had the cage installed by Dennis Bros. and then Black Art Designs corner-weighted the car. I’m running a custom set of their GT1 dampers on the car, so it was only right to let them set it up! I finished installing the Corbeau seats, harnesses, flocked dash and other safety equipment, and it was ready for the track!” Reed says with a smile.

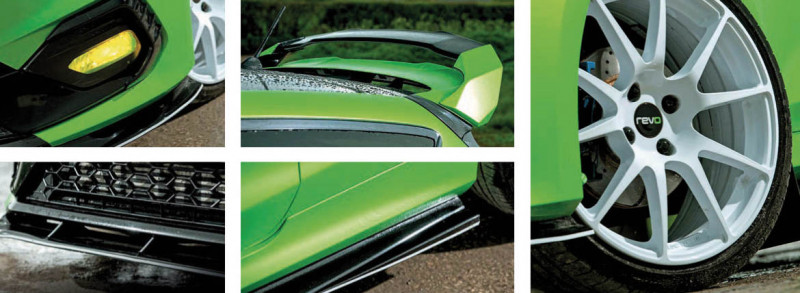

With the MeisterR coilovers and polybushes handling the handling, on the braking front, this Fiesta’s been fitted with ST170 front brakes and ST150 rears, both equipped with Ferodo DS2500 pads. A set of Team Dynamics TD1.2 16s in white have been added, wrapped in super-sticky Yoko AD08R track tyres, and they offer a tasty contrast against the Celebration Green bodywork. The interior, meanwhile, features a custom switch panel and an OMP steering wheel, along with an Acuity adjustable short-shift, and the white rollcage ties in perfectly with the wheels.

“After a few years of track days, including trips to the Nürburgring, 100bhp just wasn’t enough anymore, and I decided to increase the power, originally intending to double to 200bhp, 250 max,” Reed explains. “I was initially going to turbocharge the factory 1600cc Sigma engine, but turbo-specific parts are so scarce for this engine that I looked at other engines that are rich with upgrades in the aftermarket,” and this led him to look to the east. “After my last track day in 2019, and with Covid leaving me no track days and lots of time to think about things to do with the car, I decided to instigate Phase 2 and replace the Yamaha-designed Ford Sigma engine with a Honda K-swap,” he says. “One thing Ahmed always taught me was: do not expend torque for power, and that drove me to pick up a used K24A3 engine from a Honda Accord Type S. These come with 190bhp from the factory and have a fantastic spread of torque,” he explains, and that would instantly almost double the power output of Reed’s Fiesta, but he was only just getting warmed up.

“A friend of mine (Sam at ARC Autosport) designs and manufactures a complete turnkey solution to build your own ‘Fonda’,” says Reed, but that would have been far too easy. With his experience in building project cars and his technical know-how, he decided to roll up his sleeves and get cracking himself. “I decided to just use the engine mounts from the conversion kit and then designed all aspects of the build, from turbo spec to wiring diagrams. It kept me busy during Covid!

“I prepared the engine by installing an upgraded oil pump, larger capacity sump with gated baffles, new chain/guides and so on,” he continues. “The sump was modified for turbo oil return by Marc at Kinzy Fabrications, and I did the physical engine swap myself at home with some help from Mike at Plopsport. After the removal of the original engine, Brad at Brownside Customs cleaned up the engine bay, treated any oxidation and painted, ready for the new engine to drop in,” and the bay looks so much better for it.

“I don’t do fabrication, so I leaned on the excellent hands of Paul at Coopers Engineering for exhaust, intercooler pipework, shifter mount, tanks and other general fabrication work,” Reed continues. “Paul has an exceptional eye for detail and was happy for me to do most of the design work, turbo placement and pipework, but I definitely learned a few things in the process.

“The mammoth task of splicing together the Ford chassis loom, Honda engine loom, along with a standalone ECU with a bunch of additional sensors, was performed by myself,” he says, and that’s not a project we’d fancy tackling. “I tried to retain as much of the OEM wiring, modules, relay/fuse box as possible and interface in a similar way to how an OEM would. This took considerable planning and deciphering wiring diagrams (the Honda service manual is thousands of pages!), but it was worthwhile because only one wire out of over a hundred required rethinking!” and that’s seriously impressive.

The K24 itself boasts an impressive array of mods, chief among which is the turbo itself. It’s a Turbonetics T3/T04E hybrid that’s equipped with a TiAL 38mm twin-port watercooled external wastegate, but there’s no screamer pipe here, and it’s plumbed back into the exhaust to keep the decibels down. From there, a 3” stainless downpipe leads to a Scorpion stainless exhaust. At the business end, there’s a BMC CDA carbon airbox, while an Airtec intercooler helps to chill the intake air, which is fed to the high-revving K24 via an FN2 high-flow intake manifold. The fuelling is taken care of by a set of Mitsubishi Evo X 550cc injectors and a Clockwise Motion billet fuel rail, with a fuel swirl pot ensuring no starvation occurs on track, while a Walbro 255lph high-flow pump gets the fuel moving.

Of course, none of that would be any good without the proper engine management to oversee it all, and Reed went all-out to get the best. “The number one thing that makes driving the Snotrocket a fantastic experience is the ECU,” he enthuses. “I’ve been good friends with Baldur, owner of Baldur’s Control Systems, for over twenty years, and he flew over from Iceland to help me with the calibration of his motorsport LPC8 ECU installed in the Snotrocket. His products are next-level, offering motorsport-grade precision and immense flexibility,” he adds.

“I retained the original Fiesta instrument cluster, and we fully reverse-engineered the Fiesta CANbus so we had full control of the cluster functions, including being able to display custom messages on the dot matrix display – this will come in very handy in the future for displaying sensor readings and fault codes,” Reed tells us, and that’s an impressive addition to the whole setup. “We have also interfaced with the factory Bosch ABS module and are using individual wheel speed data over CAN to feed into the traction control strategy within the LPC8 ECU.”

The finishing touch was to get everything running perfectly and to make the most of what the boosted K24 could offer. “After initial mapping on the road, I hired TDI South’s fantastic hub dyno so we could optimise the boost control, VTEC switch point and variable cam timing calibration,” he explains. “Further road mapping was conducted to improve driveability. The objective was to keep the power at a safe level to be reliable repeatedly on track, and focus on driveability and torque control to give the maximum driving enjoyment and predictability,” and all of that combines to make this Fiesta an absolute hoot to drive. Reed was aiming for 250bhp when he set out on his Honda engine-swap odyssey, but he’s ended up with 345bhp and 295lb.ft of torque. It’s no wonder he’s christened this car the Snotrocket, and it’s an absolute riot on track.

And the track is the Snotrocket’s home — it’s what it was built for, after all. “With the radical transformation, I will be testing at local circuits this year and hope to venture over to Europe in 2024! I also enjoy taking the Snotrocket to various shows across the UK, showing it on our club stand. I’m looking forward to seeing people’s reactions this year with the new powerplant!” grins Reed, and even die-hard Ford fans would have a hard time not being impressed by the sight of that massive turbo strapped to the side of the K24. This is an absolutely awesome machine that monsters any circuit you throw at it, or throw it at, and when it comes to building cars, it’s clear that Reed’s got a real nose for modding…

“I decided to just use the engine mounts from the ‘Fonda’ conversion kit, and then designed all aspects of the build, from the turbo spec to the wiring diagrams. It kept me busy during Covid!”

Basic dash architecture remains, but in essence everything’s been gutted and reinvented.

That really is a work of art, isn’t it? The colour will be recognisable to Mk6 fans. The drivetrain, maybe less so…

“One thing Ahmed Bayjoo always taught me was: do not expend torque for power”

DRIVER SPEC REED ONLI

- AGE 45

- JOB Cyber Security

- FIRST FORD 1986 Fiesta XR2

- BEST MODIFICATION BCS

- LPC8 ECU and VTEC YO!

- FAVOURITE FORD SHOW OR

- EVENT? Ford Fair, of course

- TRACK DAY OR SHOW & SHINE? Track days!

- LESSONS LEARNT FROM

- THIS PROJECT? Always triple your expected budget

- THANKS My tolerant wife, Mike at Plopsport, Baldur at Baldur’s Control Systems, Paul at Coopers Engineering, Mark at Grove Garage, Dan at Owen Engineering, Marc at Kinzy Fabrications, John at Black Art Designs, Brad at Brownside Customs, Ford’s The Only Way. http://snot. rocks and @snotrocketfiesta

TECH SPEC MK6 ZETEC-S

- ENGINE 2.4-litre Honda K24A3, Type R oil pump, FD2 high-capacity sump, TracTuff gated sump baffle, Turbonetics T3/T04E hybrid turbocharger, TiAL 38mm BTCC twin-port water-cooled external wastegate, turbo damper, PTP Lava turbo and wastegate blankets, custom turbo oil feed and return lines with filter, MAC three-port boost control solenoid, 3” stainless steel downpipe with Thermo Met heat protection, Scorpion stainless steel exhaust system, Airtec intercooler, FN2 high-flow inlet manifold, BMC CDA carbon airbox, Mitsubishi Evo X 550cc fuel injectors, Clockwise Motion billet fuel rail, Webcon five-bar adjustable fuel pressure regulator and housing, fuel swirl pot with OEM lift pump, Walbro 255lph high-flow fuel pump, Aeroquip AQP fuel lines throughout, Mocal oil filter sandwich plate, Accusump engine oil accumulator, zinc-plated ARC K-Swap mounts, Baldur’s Control Systems LPC8 Gen3 ECU, traction control utilising ABS module, drive-by-wire/torque control, Level7 Remote sensor block

- MAX POWER 345bhp, 295lb.ft

- TRANSMISSION EP3 Civic Type R 6-speed manual, Helix 6-paddle clutch and Exedy cover, custom driveshafts, Quaife ATB LSD

- SUSPENSION MeisterR GT1 coilovers prepared by B.A.D., corner weighted, K24 hydraulic power steering pump and ST150 rack, Kinzy AN6 steering rack conversion, power steering fluid cooler

- BRAKES ST170 front brakes, ST150 rear brakes, Ferodo DS2500 pads all round

- WHEELS & TYRES 7x16” ET42 Team Dynamics TD1.2 wheels, 205/45 Yokohama AD08R tyres

- EXTERIOR Celebration Green, black door mirrors, rubbing strips and rear spoiler

- INTERIOR 6-point roll-cage in white, flocked half dash, custom switch panel, OMP steering wheel, Corbeau Sprint XL seats, Acuity Instruments four-way adjustable shifter, Lifeline fire suppression system, customised ST150 instrument cluster, full CAN integration to control factory systems, race battery located inside cabin and isolation relay