The history of boosted Porsche 911s

Porsche has been boosting its 911 for nearly 50 years – here’s how the Turbo has evolved in that time. Written by Kieron Fennelly. Photography courtesy Porsche Archive.

HOW THE 911 CONTROLS FORCED AIR INTAKE

Turbo evolution

Kieron Fennelly charts the development of turbocharging in the 911, from 1975 to the present day

The superficial attraction of turbocharging is that in harnessing waste exhaust gas energy, turbo boost offers ‘something for nothing’. While broadly true, the reality is more complicated. In the early days of turbocharging big marine diesel engines, monitoring of boost was not considered because reciprocating parts were all revolving so slowly, additional forced air simply assisted the combustion process.With petrol engines operating potentially at five times higher RPM, the equation was quite different.

Already generating up to 130bhp per litre from its competition flat six, Porsche had not given much thought to turbocharging in the 1960s. This position was soon reversed however when, having decided to race in the Can-Am series, the company realised the 917’s 300bhp deficit against the allconquering McLarens could be made up only by turbocharging. Two years in the Can-Am hothouse taught Porsche a great deal about this form of supercharging and would lead to the development of a turbocharged 911, fulfilling Ernst Fuhrmann’s aim of promoting Porsche again, as the 917s had, at the highest level in motorsport. Fuhrmann rightly saw that turbocharging the 911 could elevate it from class winner to overall victor.

Homologation meant a road-going turbo would need to be built. Porsche now had the expertise and, in the new 3-litre flat six, the engine. It would be a very cautious design: the 917 produced up to 1,100bhp: the production 930 would be restricted to a quarter of this in the interests of reliability and everyday driveability. Key to turbocharging is controlling boost level: on a racing engine, the wastegate opens when maximum boost is reached with turbine speed and manifold pressure maintained while the throttle is wide open, but the drawback is the abruptness of the boost effect, then lag, when the throttle is shut and reopened. If professional racing drivers quickly adjusted to this, the same could not be expected of owners of the new 930. Moreover, on production engines forced air to the turbines has to be cut before back-pressure to the cylinders causes overheating and eventually damages the engine.

Porsche designed the 930 to develop its 260bhp at only 5,500rpm with ignition cut-off at 6,000rpm; compression was conservative at 6.5:1 and an overboost protection mechanism intervened as soon as boost pressure reached 1.0 bar by cutting fuel supply. To counter the sudden boost above 3,000rpm, Porsche modulated boost pressure for the production 930 by employing a spring-loaded relief valve: a piston mounted in a cylinder between intake and pressure sides, which diverted boost when the driver lifted off to the intake system rather than simply voiding it through the wastegate. This had the effect of stopping the turbine spinning completely so that when the throttle was reopened, delay was reduced. Compared with today’s slick turbo installations, the 930’s lag feels enormous, but Porsche’s system was quite sophisticated in its day, better integrated than the turbocharger on BMW’s short-lived 2002, and it proved more reliable. But then development of the 911’s boost control went into almost stasis until the twin-turbo 993 of 1995, which was not to say Porsche had lost interest: developments were continuing elsewhere.

The 1980s saw the widespread introduction of digital motor electronics (DME) and Porsche’s first application was to the 1986 944 Turbo. Although the 964 too graduated to the sophistication of DME, managing the turbocharger was basically unchanged on both 3.3 and 3.6 Turbo versions and boost management as developed for the 944 Turbo had to wait until the 993 Turbo.

Besides being a masterpiece in packaging – the last air-cooled 911 Turbo incorporated not just all-wheel- drive, but also two turbochargers – it featured fully adaptive boost pressure control integrated in the same DME control box. Each turbocharger had its own integral wastegate valve operating in response to boost pressure. Rather than pressure sensors, the 993 used a hot-film sensor to determine boost pressure. This measured throttle position, engine speed, and air-intake temperature. A solenoid valve regulated wastegate openings and the OBD 2 (the 993 Turbo was the first Porsche to feature advanced on-board diagnostics) could detect misfires or any air mass-metering discrepancies that suggested boost leak or turbocharger malfunction. In this case it would permit only minimum boost level until the fault was rectified. Fault codes were stored in the DME to localise subsequent repairs.

The 996 Turbo and GT2 used an enhanced version of the 993 Turbo’s system. More accurate boost management was achieved by siting intake pressure and pressure sensors at the entry to the throttle body and as the 996 had the first 911 fly-by-wire throttle, its consequently far closer relationship with the DME allowed minute variation of the throttle position to be reflected in boost response.

Besides a positive effect on consumption (and therefore emissions) a sudden lift of the accelerator diverted boost so that the turbine would maintain more of its momentum and reduce the delay in response to a reopened throttle.

The basic principle of the 997 Turbo control unit was the same as on the 996, but with one major difference: the 997 used Porsche’s VTG (Variable Turbine Geometry).

Well established in diesel applications, but hitherto not transferred to petrol designs – Porsche claimed this was a first – because of very high temperatures (1,000 degrees centigrade) involved. On a VTG turbine, the turbine wheel has adjustable vanes or flaps: commanded by the DME, positioning of these vanes alters according to load and exhibits either the quicker response of a small turbocharger or the volume of a larger unit. A useful comparison is with the old fixed-blade engine cooling fan which runs at crank speed and the electrically operated fan all cars have had for years, which simply cuts in as mandated by a thermostat rather than churning away at fixed speed mostly unnecessarily. This capacity to control boost pressure within the turbo meant that the classic wastegate valve was no longer needed.

Model year 2017 saw something of a sea change: all 911s were now turbocharged. The Carrera and Carrera S both used twin convention turbochargers with internal wastegates, their electronic operation ever more stringently controlled; the traditional 911 Turbo, the 991.2, carried on with the VTG system introduced in 2007, and with further detail electronic enhancements would continue on the 992 Turbo. By contrast the 992 Carrera retained established wastegate turbocharging, but with electrically driven solenoid control of the wastegates: Porsche claims that this allows faster warming up of the catalytic converters to ensure they are fully operational within ten seconds. Although manufacturers are increasingly having to devote resources to electric traction, in the few years remaining for the development of petrol engines, Porsche will no doubt extract further smart technology-driven refinements from its boost-control systems.

TOP 993 Turbo was the first 911 to utilise DME boost pressure control

ABOVE The 997’s adaptive VTG vanes in action

LEFT Mid-1970s nat-asp and turbo’d 911 engines.

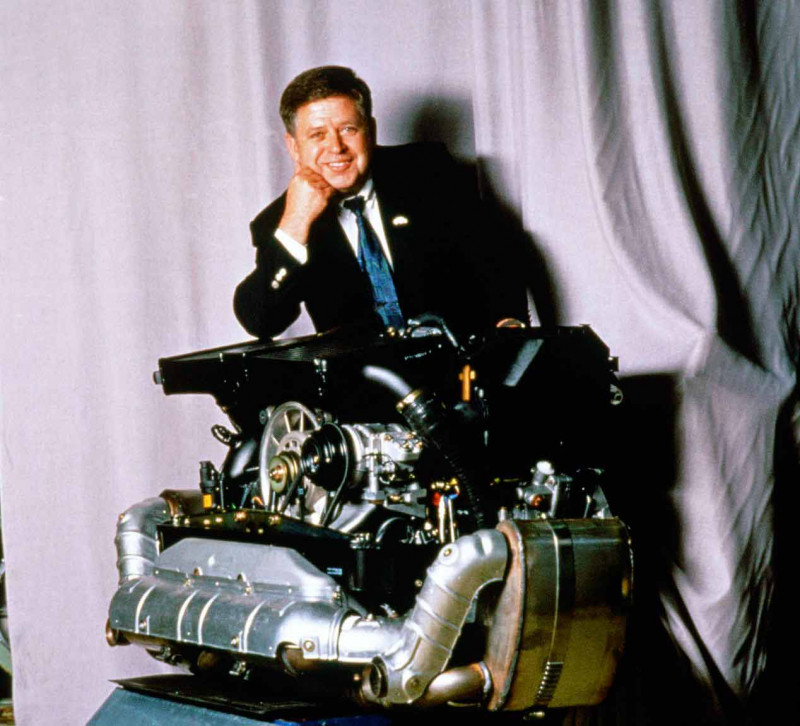

ABOVE Porsche’s Turbo engine developer Heinz Dorsch with the 993’s twin-turbo flat six

BELOW Cutaways of early (930) and late (997.1) turbochargers, plus the 930 3.3 with its revolutionary intercooler on top of the flat six, which the 992 Carreras mimic today

“Fuhrmann rightly saw that turbocharging the 911 could elevate it from class winner to overall victor”