350bhp G model Porsche 911 based Sportec’s SUB1000

Total 911 examines the latest Porsche-based restomod to hit the market… introducing the SUB1000 from Swiss racing outfit Sportec.

Written by Wilhelm Lutjeharms

Photography courtesy Sportec

‘SUB1000’ RESTO 911 DRIVEN

New restomod using modern tech in a sub-1,000kg chassis

The clue’s in the name: a 911 that weighs less than 1,000kg. The good news is that this figure isn’t a dry weight, but a wet weight. Even if you fill the SUB1000’s 64-litre fuel tank you’ll still be sitting in a car that weighs just under a tonne.

This is arguably the most exciting time for 911 enthusiasts: never before has there been such a wide offering of OEM 911s, as well as custom 911s and restomod 911s. Indeed, the amount and variety on offer appears to be growing on almost a monthly basis. A lightweight 911 isn’t a straightforward proposition though, because a specific approach is needed to lower the weight. However, if you’re a motorsport outfit – like Sportec – then you’re well placed to make all the necessary alterations.

Back in issue 227 we featured Sportec’s handiwork in the shape of Project Ferdinand. The SUB1000 is a rebuild of sorts of that project, but owner Gregor Burkard admits that the idea of the car we’re looking at on these pages came before Project Ferdinand. During a video interview with both Gregor and Raphael Jaggi, who’s heading up the company’s classic department (Sportec Classic), I can see from Gregor’s facial expressions and hand gestures that his passion and enthusiasm for his company, staff and his dreams are evident and real. “I come up with crazy ideas, and Raphael needs to turn it into reality,” he partially jokes when we start the interview.

The latest 911 restomods based on OEMs are impressive, but if we’re being honest most of these cars are very heavy (although very safe) and are only exciting to drive at fast speeds. Gregor’s aim was to offer an alternative at the opposite side of the spectrum, in the form of the SUB1000.

Gregor explains: “The idea came up in 2020. Because we had a number of clients who requested a car such as Project Ferdinand, we had to push back the SUB1000 project. However, we started the project three years ago.”

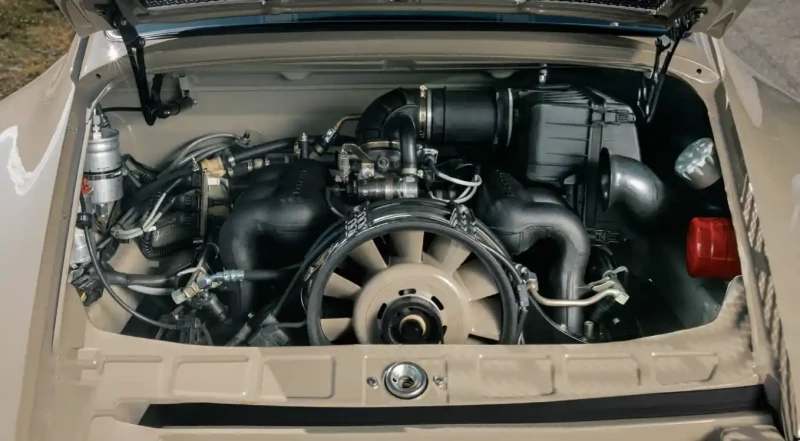

Raphael says, “The base car is a 911 from between 1987 and 1989. It’s the last G model with the 3.2-litre engine. However, what’s also important is that it came with the G50 gearbox during those final years. One of the other reasons we choose this model is that the G series is lighter than the 964 series. The approach from the beginning was to keep only the absolute essentials to be able to drive the car. There is, for example, no air conditioning and barely any heating. There’s only a little heater to de-fog the windscreen. It doesn’t even have ABS brakes or power steering. The result is a good base to make a really lightweight car.”

Raphael explains that there’ll be two versions to choose from when it comes to the SUB1000, to widen the appeal of the car. “In both variations we’ll take the base engine, before rebuilding and developing it. For the first model we’ll increase the engine’s capacity to 3.4 litres following a complete rebuild with new pistons and crankshaft. We also install individual throttle bodies, a larger oil pump and a stronger fuel pump, to name but a few. The result is 350Nm and 300bhp.” These figures are achieved around 4,900 and 6,000rpm, respectively. It’s clear that the SUB1000 is no high-revving unit. Instead, the driver will already feel the level of performance thanks to the car’s lightweight nature.

This is not the only engine derivative that will be offered in the SUB1000. Another version will feature a larger air intake, different pistons and a host of additional upgrades, with the goal of producing 350bhp. The engine’s capacity will remain the same and Raphael admits this makes it a real challenge, because they’ll have to take a dive deep into engine building to achieve this level of performance.

However, this will take the driving experience to a new level. After all, 350bhp per tonne is an impressive figure, in line with some modern high-performance sports cars such as the 992 Turbo.

It was Gregor’s dream to offer such a car, so it’s no surprise that he’s part of the development process. “I’ve been driving our development car now for a number of days,” he says. “It’s honestly impressive how fast a car gets and is dynamically capable when the weight is this low. Our plan is to reach 350bhp with the high-performance option and homologate the engine here in Switzerland, as well as for Europe.”

As expected, the process of weight saving has been thorough to say the least. All the panels of the SUB1000 are made from carbon-kevlar composite materials. These include the doors, fenders, bumpers, and the front and rear lids. Even the roof has undergone significant change. The donor car that Sportec acquired was fitted with a sunroof, and this was removed and the panel was replaced with the composite material. Take a closer look at the footwell, and it’s evident that any unnecessary equipment and materials have been removed. Apart from two panels and the set of pedals, all there is to see is the clean, metal floor of the car.

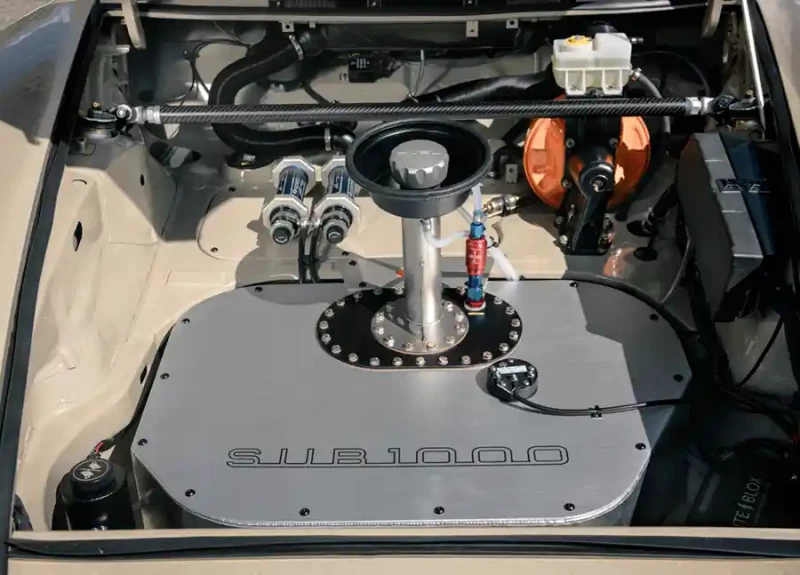

Raphael elaborates on other significant details of the car. “The wheels are CNC milled, forged aluminium wheels. They’re pretty lightweight. Of course, one can make carbon-fibre wheels, but that would be a completely different story. A racing fuel tank further saves weight and so does the new wiring loom. Because a lot of the original features have been deleted, the new loom is markedly lighter than that of the original. At the front we’ve fitted an aluminium FIA-specification 64-litre fuel tank that features a bladder within the tank.” The filler rises beautifully from the tank to the centre of the front lid – a reminder of racing 911s from the past.

“In terms of the suspension, we took out the torsion bars and changed it to coil-over suspension. We use a three-way system and it offers separate reservoirs where we can adjust the pressure. This allows us to adjust the compression and rebound separately. It took us some time to set it all up, because we also had to go with softer springs thanks to the lower weight of the car. Together with Marcel Fässler [the retired Swiss racing driver] we’re still testing and fine-tuning the system – there’s just so much to adjust.”

Gregor explains more about some of the interior elements in the cabin: “When I started to think what the cabin of the SUB1000 should look like, I thought about this specific way of stitching from some furniture I’d seen. I thought we should combine the vintage leather with this type of stitching. It took several weeks to find the correct leather and have it stitched in the exact way I imagined. I really hoped it would look good, and thankfully everyone up to now has said it looks wonderful. I’m really happy that I’m not the only one who thinks it looks perfect! The leather is from Italy and is made to look like aged leather.”

The seats are undoubtedly one of the highlights of the cabin. The “aged” leather combined with a modern design of the carbon-fibre seats is a beautiful contrast of old and new. The gearlever is also CNC machined and anodised, and features a ribbed gear knob that should offer a high level of grip.

The gearbox features a short-shift system, while the solid bearings assist in minimising the play when shifting gears. The brake system is also unique: it features the setup from the 930 Turbo in terms of discs and calipers. Raphael explains that this was also a challenge, because you don’t want to over-brake the car: it’s much lighter than a 930 Turbo and you could run into problems with brakes locking up all too easily. “We’re now at a stage where there’s really great feedback to the driver through the pedal and where he or she can adjust it easily with their foot.”

Another highlight in the cabin is the two Hanhart stopwatches, neatly placed below the dashboard on the passenger’s side. “These watches are built by order according to the client’s specifications. There are a number of reasons we fitted these: one of them is simply the way they look, and also because they’re mechanical, so you need to wind them up. One is a watch and the other is a stopwatch. We want owners to really use them at rallies.” As one would expect, the car is also fitted with a limited slip differential, especially necessary for those tight hairpins scattered throughout the Swiss Alps on nearly every mountain pass.

The final words go to Gregor: “There’s still scope in the future to make it a little lighter, but for now we’ve set a goal and we’ve reached it. It’s not 999kg, but even less. The SUB1000 is our puristic, driving machine – even with a full tank of fuel it’s still below 1,000kg. That is why we went back to the roots.

What’s important with this car is that the driver feels the car and what it’s doing. The watches are just a small touch to take the occupants of the SUB1000 back to a time when these cars were used to race.” The SUB1000 will cost 370,000 Swiss Francs (£333,000) without a donor car. As expected, a client will be able to be part of the process from day one, ensuring a high level of individualisation. Rightor left-hand drive SUB1000s can also be built, depending on the configuration of the donor car. Now, how can we find our way to Switzerland to drive it…?

ABOVE The aged leather seats are a highlight of the cabin, which take their inspiration from furniture that Sportec’s owner Gregor Burkard had spotted.

RIGHT While the donor car is a G model 911, Sportec’s SUB1000 takes some exterior design cues from the F model, such as on the bumper.

ABOVE The minimalistic gearlever controls a short-shift gearbox system, and is topped by a custom ribbed gearknob that’s made from aluminium.

ABOVE The base car had a 3.2-litre engine, but this has been worked on by Sportec’s engineers and is now a 3.4-litre powerplant.

ABOVE More weight has been saved by using CNC-milled aluminium to form the SUB1000’s wheel rims.

RIGHT Sportec’s SUB1000 utilises thinner glass in the rear window compared to the donor’s original, along with carbonkevlar composite materials in the car’s body panels.

RIGHT Sportec overhauled the donor car, looking for ways to reduce weight. The side windows are made of Makrolon polycarbonate, for example.

ABOVE In a nod towards Porsche’s racing legacy, the fuel filler can be accessed without lifting the bonnet of the car.

RIGHT Retired Swiss racing driver Marcel Fässler is assisting Sportec’s engineers during the testing of the SUB1000’s suspension.