2.8-litre VR6 conversion with GT3582 turbo 530hp Volkswagen Golf Mk2

Some people go to college to learn about automotive engineering, but David Olsson went down a slightly different route… Words: Bryan McCarthy. Photos: Mike Kippen.

THE ROLLING CLASSROOM

Who here can remember the first time they were handed a wrench and told what to do with it? For some, the earliest memories are the ones that stand out the most. For our man David Olsson, he always possessed the desire to build things and understand how they work. Watching his father figure out the mechanics of a problem and engineering a solution sparked an interest that’s still burning to this day. “I remember one project my dad took on when I was younger was he took a 1951 Studebaker truck and put the body of it onto a 1994 Ford Explorer frame so he could get the newer technology and the 4WD.” Whoa.

Unable to quench the insatiable thirst for knowledge and know-how, the Mk2 you see before you is his interactive learning environment. And while it appears he’s at the top of his class, there isn’t a graduation date in sight. No sir, he’s still learning.

There are countless ways to “complete” a project car. You can write a cheque and ship it off to your local garage, hoping they see your vision through to the end. Or you can roll up your sleeves and invest some sweat equity into your pride and joy. But regardless of input, what’s it take to build a stand-out car these days? For a chassis like the Mk2, you would think that everything under the sun has been done already. Shiny paint, mortgage payment wheels, and dunked in the weeds are all you need to be the next wanker in the winner’s circle. Oh, and Pit Viper sunglasses, apparently. Insert roll eyes emoji here.

For 30-year-old Olsson, his Mk2 is a rolling studio for a never-ending learning experience. YouTube tutorials have nothing on this handson project. But it’s the details of this build that really set it apart from others like it. And by like it, we simply mean Tornado Red paint, mesh wheels and a Rallye front end. And while the combination of a VRT and AWD might not be unique in a tuning sense, we implore you to read on to see just why this Golf is in a class of its own.

“I’ve had this Mk2 for about 10 years or so,” the Vancouver, Washington native tells us. “I owned it my senior year in high school for a bit, sold it, and bought it back a couple of years later. That’s when the project started.”

Like many, an experience was all that was needed to set the course for a lifetime of marque devotion. “I first got into MK2s when a buddy I met in high school had a Mk2 VR6 GTI and he took me for a ride. After that, the obsession started.” If we had a nickel for every time someone told us that…

While still in high school, David landed an internship through a tech program at Double J Motorwerks and has been there ever since. “Joey Marstall, the owner of the shop, took me for a ride in a 530hp VR6 turbo MK3 Golf he had built and I was blown away. I knew after that I was going to build one.”

“When I started the Mk2 project I didn’t really have a plan,” David candidly informs us. “The car was rough. I mean really rough. Spray painted two colours and dented everywhere. I immediately stripped the car down and towed it to my buddy’s shop where he worked his magic and got the car straightened out and painted. When I got the car home from the body shop and it was just a bare painted shell sitting In the garage, that’s when the ideas really started flowing. I decided this was going to be the car I built a VR6 turbo for.”

Without knowing where it came from or how it came to be, it would be easy to walk past and dismiss it as another VR-swapped Mk2. The exterior is perfection in that simple sort of way: the single wiper, Rallye front, G60 flares, and dialled in stance. Look a little closer and you’ll find pop-out rear windows, a cleverly placed VR6 badge on the back, and an intercooler lurking in the front bumper. Inside you’ll notice Recaro SRD seats with custom fabricated mounts to get them as low as can be, and a Corrado dash so its cluster could be used. All fine choices for his modification modicum. But where this car really shines are in the details you can’t see right away.

The automotive tech program in high school helped to focus David’s career sights and starting the internship at Double J really narrowed it in. In fact, David has been there ever since, with his current position as a full-time service manager for the Portland, Oregon business. “Joey, my boss and mentor, has taught me so much over the years and lots of those skills I’ve been able to apply to this build,” says David. “From there I’ve just dedicated all my free time to either online classes or weekends at the shop getting hands-on experience.”

Pop the hood and the first thing that stands out, besides the fact it’s a VR and not a 16v, is the location of the turbo. “It’s no secret that a VR6 turbo Mk2 isn’t anything special anymore and at this point just about anyone can put one together,” muses David. “That’s why I wanted to be a bit different with mine. That’s where the turbo location came about. I wanted the engine bay to have a different feel than the usual VRT builds and I really wanted it to be aesthetically pleasing to the eye.” He certainly nailed the mission in this case. “Gabe Villalpando is the genius behind the turbo manifold fabrication. I was lucky enough to share a work space with him for a few years and I learned so much. It took awhile, but eventually he started sharing some of his secrets with me.” Take a gander at the engine bay and rest easy knowing you can finally put your finger on what makes it so memorable.

And not wanting to just bolt a snail to a hand grenade, the 2.8L VR6 was also stripped and rebuilt. The rings and bearings were replaced, and ARP rod bolts and head studs were added. Techtonics Tuning 276 camshafts were also utilised. “Joey built the exhaust system which is 3” oval to aid with clearance,” says David. “I fabricated the intercooler, boost pipes, catch can, transmission mount, radiator mounts. I converted the entire fuel system to -6 AN hoses. Anything that wasn’t needed was removed. I stripped the wiring harness down and removed anything I wasn’t using. I bought a PNP adapter to run a VEMS Standalone ECU. With the non existent support from VEMS and their dealers It gave me a real chance at learning to tune. I relocated the battery to the hatch and fabricated a battery mount.” There is one other thing you might not notice that we found amusing. «The VR6 has a goofy tilt to it and it always bothered me,” laughs David. “So when I built the new transmission mount I made sure to level the motor.” Details matter.

The car was dyno’d and made just under 400 horsepower with a GT3582 turbo. However, the limits were clearly met from the front-wheel-drive platform. It was time to correct that.

“Converting the car to all wheel drive has probably been my favourite project with it so far,” says David. “I estimate it took probably 350 hours and it was spread out over the course of eight months and I loved every second of it.” Let us remind you that the car on these pages was not the result of a chequebook assault or an auction win. Most of the work was completed by David’s own two hands and his unwavering dedication and desire to learn. Don’t know how to wire something? Cool, let’s read some wiring books. Engine needs assembling? Let me show you this VR on which to learn. There wasn’t anything that David wouldn’t attempt on this car. It’s his platform for learning and the all-wheel-drive conversion was about to be his pièce de résistance. For starters, David used a Quantum Syncro wagon rear beam for its ease of sourcing.

However, easy parts availability doesn’t necessarily mean it’s a bolt-up affair. “The first [issue] was the off-the-shelf rear Haldex brackets don’t fit the Quantum beam. That meant I had to fabricate my own rear Haldex support.” David used chromoly tubing and built custom brackets off the body to tie everything together. Done, right? Not yet.

“The next issue was the Quantum beam sits much taller. So when I built the custom rear floor I had to make clearance for that.” While it may sound easy just reading the procedure on paper, keep in mind the amount of time and effort it took to get this right. “I used a Mk4 R32 transmission, angle drive, and Haldex.

The driveline was from a Mk1 Audi TT. The axle shafts are custom due to the lengths needed.” “Here’s where the fun started,” David continues. “The Quantum rear control arms use an oddball wheel bearing size. I knew I wanted to [use] Mk4 R32 rear axle outer joints so that meant I had to use a hub that would fit. I ended up with Mk3 VR6 hubs. The issue is they didn’t fit inside the Quantum wheel bearing and they were 5x100 and my car is 4x100. So, I sent the hubs off to a machine shop to have them redrilled and machined down to fit inside the wheel bearings.” Again it shows that David stopped at nothing to achieve the goal he had in mind.

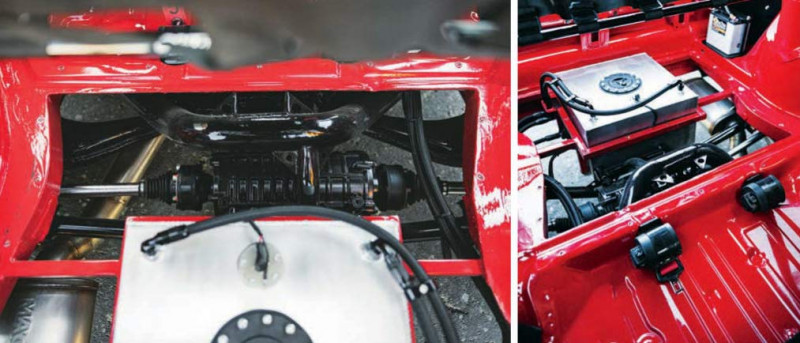

Now, how enjoyable would a Broadway show be if the curtain never rose? All of David’s talents are on full view thanks to a removable rear floor. His fabrication skills are impressive and would certainly achieve the Most Likely To Succeed accolades in the proverbial year book.

Sometimes choices are made out of necessity rather than want. “I used a fuel cell because sourcing a factory all wheel drive fuel tank was too difficult and it wouldn’t have fit with the custom floor anyways,” David explains. “Of course, the fuel system needed to be completely redone. The driveline didn’t fit because it hit the body. So I cut the tunnel of the car and raised it just enough to clear the driveline and still allow the factory carpet to fit. The shift box had to be moved inside the car to make room for the driveline so I built a custom shift box.” The more David elaborates on what went into making this all-wheel-drive system happen, the more it seems like his return on eight months time invested was well worth it.

Cue Billy Mays with his ear worm catchphrase. “Then came the fun of trying to control the Haldex. An aftermarket controller was out of the question due to budget reasons. Instead I tracked down the VW self study guides for the Haldex and tried to get a better understanding of how it worked.

I ended up taking the Haldex apart and modifying it. By doing so I could run the pump off a switch. Anytime the switch is pressed the pump turns on and the car is locked 50/50.” How many people at your Thursday night get together will go to those lengths to get a certain function working? We’ll wait. “I’m definitely most proud of the all wheel drive conversion,” beams David. “It was a huge undertaking and the feeling when I saw all four tires spinning while on the lift was surreal!”

The car was finished to its current state in 2019. But let’s be honest, an owner with the mind and capabilities that David possesses it will never be complete — it’s a dynamic project that evolves with the times and talents of its title holder. “The car is a blast to drive on so many levels,” exclaims David. “It’s fast enough to get your adrenaline going and the way it hooks with the all wheel drive is such a rad feeling! Anytime I drive the car it brings back all those memories from high school and makes me feel like a kid again.”

While it wasn’t built to be a show car or a race car, it still placed at both shows it was entered in, a testament to David’s impressive work. Otherwise, if it’s at a show you can usually find it parked at the Double J booth. As this semester wraps up the inevitable questions gets asked, is it a keeper? “This car is definitely with me for life,” David professes. “I have no intention of ever selling it. It means far too much to me.” Next up on the schedule is a 300-level course of rewiring the car front to rear, updating the ECU and the electronics to something newer, another challenge that David is more than up to. “My main focus now is to really push my knowledge and skill set on electronics and what better way to learn.”

Finally, a bit of extra credit for our readers. “A fun fact about the car is technically I don’t even own it, my mom does. When she bought it for me the first time I owned it she put it in her name. And even after it passed hands a few times no one ever registered it. So when I got it back I just left it in her name. She likes to joke that whenever I modify it I need to ask her permission first.”

»I have no intention of ever selling it. It means far too much to me"

DUB DETAILS

- ENGINE: 2.8-litre VR6 conversion with GT3582 turbo, 02M 6 speed gearbox with a Haldex 4motion, VEMS ECU, Techtonics Tuning 276 camshafts, Deka 630cc injectors, AEM 400lph fuel pump, fuel cell with a hydromat, custom 3” turbo-back exhaust, custom intercooler and boost pipes

- CHASSIS: custom removable floor, Quantum Syncro wagon rear beam, custom fabricated rear diff mount, custom axles

- EXTERIOR: Pop out rear windows, Golf Rallye front end, G60 fender flares

- INTERIOR: Corrado dashboard, Mono steering wheel, Recaro SRD seats

- SHOUT: Joey Marstall, my boss and mentor. Philip Leusca has been my body and paint guy. Gabe Villalpando. The last special thanks goes to my Dad. He’s the reason I even got into cars. From my earliest memories he was in the garage building all these crazy muscle cars. He taught me a lot, but most importantly he taught me to never be afraid to take on a project. “It’s just a car and it’s just metal” he also gave up his garage for quite a few years when I started my project. He let me take it over and use all his tools which I know was a big deal to him. I’m forever grateful for all the support I’ve been given during this wild ride with this car.

«Converting the car to all wheel drive has probably been my favourite project with it so far»