Buying Guide 1967-1972 Aston Martin DBS

Discover what to look for and the costs involved in buying, owning and running a six-cylinder or V8-powered DBS.

WORDS ROB HAWKINS

IMAGES AMD ARCHIVE

What to look for when buying one of the great-value classic Aston Martins, the DBS from 1967 to 1972

1967-1972 Aston Martin DBS BUYING GUIDE

Manufactured between 1967 and 1972, the first generation of the DBS paved the way for a new style of Aston Martin that became a success well into the Eighties. The American muscle car inspired shape was penned by designer William Towns and wasn’t intended to replace the DB6 (the two were produced together until the DB6 ended in January 1971). The original plan was to install an all-aluminium V8 engine, but this had been unreliable at Le Mans in 1967 when installed in a couple of Lola T70s, so it was postponed, and the DBS was launched with the familiar 3,995cc straight-six engine that powered the DB6. It wasn’t until the spring of 1970 that the V8 was finally installed and both engines were fitted until the model was revised in 1972 after owner David Brown sold Aston Martin, and available only with a V8, it was renamed the AM V8.

Total production of the DBS under David Brown amounted to 803 in six-cylinder and V8 guises with the Vantage badge offering more performance. And it was only ever available as a four-seater sports saloon – there was no convertible Volante until 1978.

Whether it’s a six-cylinder DBS or a V8 (commonly known as a DBS V8), these four-seater fastbacks are now collectable classics, and still offer the looks and performance to match. Motor magazine tested a Vantage-specification six-cylinder DBS for their 21 December 1968 issue, reporting a 0-60mph time of 7.1 seconds and a top speed of 141.5mph. According to the website astonmartins. com, the DBS V8 with a manual gearbox can hit 60mph from stationary in a mere 5.9 seconds and achieve a top speed of 161mph. At the time of manufacture, it was one of the fastest production cars in the world.

The standard of specification is also very impressive for a classic from the Sixties and Seventies. All models had electric windows, disc brakes all round with two servos, a limited-slip differential, power steering, air-conditioning (optional) and either a five-speed manual or three-speed automatic gearbox.

Paul Richards at Richards of England says, “A manual gearbox is much more suited to the six-cylinder, even though you can convert, but sourcing an original manual is much more desirable. The V8 is much happier touring with an automatic gearbox. However, a manual is still the one people want.”

PRACTICALITIES

The DBS looks large, and it is, at 4,585mm or a little over 15 feet long and 1,829mm or six feet wide. Surprisingly however, it’s marginally smaller than the last of the Ford Mondeos (2015-2022).

Inside a DBS, there is space for four people, but with seatbelts only for the driver and front seat passenger. With aluminium bodywork and a steel chassis, the DBS is not too heavy at 1,588kg for the six-cylinder and 1,727kg for the V8. Consequently, fuel consumption should be in the teens and 20mpg at best, but as low as 10mpg if you are heavy-footed. With a 21-gallon fuel tank, it’s feasible to cover 200-400 miles between refills.

Working on these vehicles requires a selection of imperial AF tools, and lifting equipment such as a two-ton trolley jack and substantial axle stands are required to safely raise and support the vehicle, whether you are changing a wheel, working on the brakes or rust-proofing the underside.

Darren Wood at Aston Service Dorset (ASD) explains that a special tool and a dial gauge are required to set the preload on the wheel bearings, although an old driveshaft can be used instead. Otherwise, no special tools are required to work on these vehicles.

VALUES AND COLLECTABLES

Expect to pay upwards of £100,000 for a DBS in roadworthy condition, but if originality is a must, you may have to pay a higher price for a genuine example. These cars weren’t worth much during the Eighties, so an engine swap or a roof chop to turn one into a convertible were not regarded as spoiling the originality. While a DBS with a different engine will probably reduce the value of the car, a Banham convertible is regarded as collectable and potentially more valuable – Paul Banham completed around 30 convertibles in the late Eighties and early Nineties (see issue 4 for a feature on one of them). The first generation of the DBS (known as the series one or Mk1) features louvres behind the rear side windows to aid airflow through the cabin. This was replaced with a single louvre above the bootlid in 1970 (and is a feature of all DBS V8 models) when the series two or Mk2 appeared. Very early models also had a split front bumper with the registration plate mounted in the middle.

The V8 models have a larger front air dam than the six-cylinder models and are only equipped with 15x7in GKN alloy wheels — wire wheels were only fitted to the six-cylinder engine DBS as they were deemed insufficient to handle the power and torque of the V8. According to the website, www.astonmartins.com, 402 DBS V8s were produced between April 1970 and May 1972 before the AM V8 replaced this model.

It goes on to say that the gold DBS featured in the television programme, The Persuaders, which was driven by Roger Moore, was badged up to look like a V8 model along with the GKN wheels that were only fitted to the V8, but it was actually a six-cylinder because demand for the V8 was so great that AML could not supply one for filming.

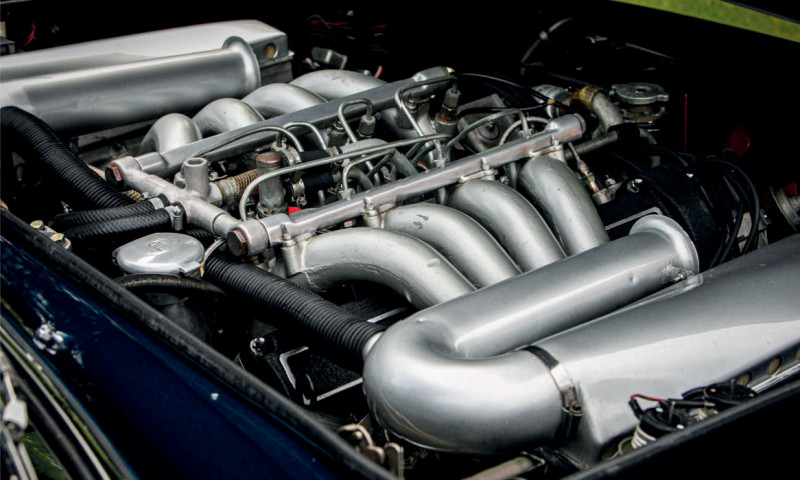

SIX CYLINDER

The DBS’s all-aluminium six-cylinder engine in standard tune should produce 282bhp at 5,500rpm. It’s equipped with a bank of three SU HD 6 carburettors and has an 8.9:1 compression ratio. The Vantage model of the DBS used the same engine, but its compression ratio was raised to 9.4:1, the camshafts were reprofiled to improve performance and triple DCOE Webers replaced the SUs, resulting in a power output of 325bhp at a higher 5,750rpm.

Listen for excessive tappet and timing chain noise, which is often more prominent on high-mileage engines. Check the oil pressure is around 30psi at idle when the engine is warm. “Check the weep holes on the side of the engine block for oil,” says Paul Richards at Richards of England, concerning common oil leaks on this engine. He goes on to say that a common problem is a crack emerging in the engine block near the cylinder liners, which can only be seen once the cylinder head has been removed. Paul says it can sometimes be repaired by laser welding the crack, although in some instances a new engine block is required.

Darren at ASD adds that the six-cylinder engine block is prone to corrosion around the base of the liners. “This can require the block to be sleeved to provide a good surface for the O-rings on the liners to seal against, which costs £2,500-3,000 to sleeve all six liner registers.”

He also says that oil leaks from the rear main oil seal are common (it uses a scroll seal), so look for oil drips from where the engine and gearbox are mated. “We stock an easy-to-fit lip seal conversion which can be fitted during an engine rebuild which eliminates this problem,” he says, which costs £277.56.

If an engine rebuild is required, then stretching the capacity to 4.2 litres is a tempting upgrade and not much more expensive than a standard rebuild. Including dyno testing, budget for around £33,000.

TRANSMISSION

A ZF five-speed manual gearbox was fitted throughout the production of the DBS, but an automatic gearbox was also available. For the six-cylinder engine, it was a three-speed BorgWarner BW8, whereas for the V8, it was a Chrysler three-speed TorqueFlite. However, as David at independent specialist Borg Warner Specialist explains, “I have seen people use the BorgWarners in their V8s, so people may have interchanged them over the years.” He charges £895 to rebuild a BorgWarner BW8 and £350 for the torque converter.

All models were equipped with a limited-slip differential (LSD), with a 3.54:1 final drive ratio for an automatic gearbox and 3.73:1 for a manual.

Check that the selection of gears on automatics is smooth when changing up and down. On a manual gearbox, listen for the clutch slipping, check the biting point (it’s a hydraulically operated clutch) and ensure none of the gears jump out of selection. Gear selection on the ZF may be a little awkward at first when the oil inside is cold, but this should become easier as it quickly warms up – if it doesn’t then further investigation is needed.

“The ZF five-speed can suffer from a noisy layshaft when hot and the box is in neutral,” says Darren at ASD. “It requires the engine to be tuned to the best it can be and the layshaft shimming to eliminate the chattering sound, although it is almost impossible to get rid of it completely.” In all cases, listen for noises (whirring and clonks) from the gearbox, propshaft and rear axle, which could indicate worn bearings or universal joints and wear inside the differential.

The debate between choosing a manual or automatic gearbox may be resolved by what cars are available and your budget, but if money and availability were not part of the equation, what would you choose? Rupert Keyzar at The Aston Advantage explains, “A DBS Vantage with a manual gearbox is a stunning car to drive and the best of the six-cylinder DBSs by far, but a manual DBS V8 is something else when properly set up.”

WHEELS AND TYRES

The DBS was equipped with 15in wheels for both the six-cylinder and V8. “Like the late DB6, the six-cylinder DBS came fitted with either 815V15 Avon Turbospeed cross-ply tyres or 205R15 Pirelli Cinturato CN72,” explains Dougal Cawley at Longstone Classic Tyres. “Generally speaking, Aston Martin in this period fitted Avon as a cross-ply and Pirelli Cinturato as a radial. We recommend the 205VR15 Pirelli Cinturato CN72 for the six-cylinder DBS.”

As for the DBS V8, Dougal says, “Lowprofile tyres came out in 1968. The DBS V8 came out with GR/70R15 tyres. I also believe it came with the Pirelli CN12, and all the period pictures look like that. We currently recommend the Michelin 225/70VR15 XWX for a DBS V8. It is smack bang period, and as well as the Pirelli Cinturato CN12, it is what all the other top sports cars of the day fitted — Ferrari, Maserati, Lamborghini, etc. We have utter faith in the carcass of the Michelin XWX as a fantastic handling tyre on very powerful cars of that period. The 225/70VR15 Avon ACR3A is what the later V8 had fitted, but to me they are a bit more of a comfort tyre and it is only capable of a V speed rating [149mph] whereas the Michelin gets a W [168mph].”

Motor magazine’s road test of a DBS Vantage (21 December 1968) comments on having low-profile Avon radials fitted, stating they were, “our favourite covers for wet-road grip. A measure of their adhesion is the staggering 0.97g recorded in a maximum stop from 40mph in the wet – better than many cars manage on a dry surface.”

Suffice to say that if you are paying a good price for a DBS, the tyres should all be the same brand and not older than seven years — look for a four-digit date stamp on the sidewall of the tyre, which indicates the week and year they were made (4812 means week 48 in the year 2012).

SUSPENSION

All models feature coil springs all round with wishbones, telescopic dampers and an anti-roll bar at the front, whereas at the rear, there’s a De Dion axle with a Watts linkage (four trailing/radius arms) and Armstrong Selectaride lever arm dampers.

“Look at the car from the rear,” comments Paul at Richards of England. “You often see DBSs leaning to one side, which is often to do with the set-up at the rear and incorrect bushes being fitted.” During a test drive, listen for clonks from the suspension, which could be caused at the front by worn bushes, or at the rear by a failed lever arm damper or worn bushes for the Watts linkage. If the car can be raised on a ramp or positioned over an inspection pit, visually inspect the coil springs for fractures and excessive corrosion.

If you are at all unsure about the condition of the suspension and whether it needs a thorough overhaul, then costs can soon accumulate, although individual prices are often reasonable. For instance, a replacement bush for the Watts linkage is around £40, but note that there are eight of them. A complete bush kit for the front suspension costs around £700. Standard lever arm dampers can be overhauled for around £800 for a pair.

Upgrades are available, such as adjustable coilovers for the front suspension and telescopic damper conversions for the rear, both of which cost around £1,000.

BRAKING

Girling discs and calipers are fitted all round with two separate circuits and vacuum-operated servos for the front and rear. The rear brakes are inboard-mounted and while there’s an access panel underneath the rear seats, they are awkward to inspect and even more awkward to work on, so if the fly-off handbrake is very poor or there are any issues with the rear brakes, don’t assume it will be straightforward to fix. The front brakes can be visually inspected from behind the road wheels, so look for corrosion of the discs. Routine maintenance should see them stripped and cleaned annually to help keep them in working order.

Being a dual-circuit system, Paul at Richards of England warns the brakes can be difficult to bleed and achieve a firm brake pedal, so if the pedal can be pumped to help make it feel firmer, there may be air in the system that needs to be removed.

Parts prices vary – a seal kit for a front brake caliper costs around £80 and a set of pistons costs £230, but excludes the work required to overhaul the caliper, whereas an exchange front caliper costs almost £350. Expect to pay around £365 for a single front brake disc, £75-£95 for a set of front brake pads, £100 for a set of rears and £165 for a set of handbrake pads. A brake servo costs around £360, and there are two of them.

INTERIOR & ELECTRICS

Check the condition of the interior upholstery, looking for fading, tears and marks. Whilst a sagging bolster can be replaced, a damaged piece of exterior leather for instance, may be difficult to source a colour-matched replacement that will blend in with its surroundings. And note that whilst most upholstery is made from leather, cloth interiors may have been fitted at the request of the customer or as a cheap replacement at some point in the car’s life.

Test all of the instruments and switches to make sure they work. Missing or inoperative components may be difficult to repair or source, so be wary of a seller who appears confident that an inactive tacho for instance, should be easy to fix – why hasn’t it been done?

A single 12-volt battery powers the electrics in a DBS, which has a positive earth connection on the six-cylinder models, but a negative earth on the V8. Exact details are not so clear, but some six-cylinder models were equipped with a dynamo (although some specialists believe all models were fitted with an alternator), but may have been upgraded to an alternator and converted to negative earth electrics (an alternator conversion kit costs around £340).

Paul at Richards of England recommends removing the polished sill covers to inspect the wiring harness that’s routed down the sides of the sills. The wiring can turn brittle and become damaged where it exits the sills, resulting in electrical issues.

BODYWORK CORROSION

With a steel framework in which aluminium exterior panels are fitted, corrosion is one of the biggest issues to look for in a DBS. Start by carefully inspecting the paintwork to look for bubbling where corrosion of the aluminium exterior has occurred. This can usually be fixed by rubbing down the affected area to remove the corrosion, then respraying the panel, but this can be costly because a small patch can result in a large area to respray and blend in with the rest of the exterior. Next, look along the edges of the wings, doors and A-pillars for further signs of corrosion.

Then move to the sills and check them from underneath and inside the cabin (if sill covers are fitted, check whether they can be removed to look underneath them), tapping along them with the soft handle of a screwdriver to check for a reassuring tinging sound of solid metal. These sections are made from steel and if they are rotten, repair panels are available that cost from £100 to £650 per side, but will undoubtedly cost a lot more to fi t and paint.

If possible, look underneath the vehicle to further check the condition of the steelwork that forms the main chassis/ platform. Look for corrosion in the two steel box sections routed parallel to the sills and up to the front, where they are connected to the suspension turrets and the front footwells and engine bulkhead. There’s potentially a lot of hidden steel underneath the aluminium exterior, all of which can corrode more dramatically, resulting in a thorough stripdown and overhaul to remove the rot. Such an undertaking will cost several thousands of pounds to complete, and there are only a few steel repair panels, such as Watts linkage mounting brackets for £80 each, so the rest will have to be fabricated.

A similar problem exists with the exterior bodywork, where new panels are few and far between, so if a replacement rear quarter is needed, new old-stock or used items are all that’s left, which means prices can be high – we found a used undertray for an early DBS for sale for £1,200.

Paul at Richards of England says that, “Other signs of corrosion are at the bottom of the A-posts around the front screen, often bubbling in this area.” He also recommends checking the bottom of the doors because water passes through them and can sit there, rotting out the door bottoms and getting between that and the aluminium skin, resulting in bubbling. “The bottom fl ange of the front wings and rear wings that rivet to the outer sill (behind the polished sill) often oxidise and crumble away,” he says. “The wing bottoms can be made and replaced whilst replacing the sills.”

Rupert Keyzar of The Aston Advantage says, “Bubbling of the aluminium body such as around the windscreen and the bases of the wheelarches almost certainly indicates chassis problems of varying degrees. A clean-looking car can hide many issues and a tired-looking car can actually be quite sound underneath – so you do have to take each car on its own merit.”

THANKS TO:

- Aston Service Dorset 01202 574727 astonservicedorset.com

- Borg Warner Specialist 07860 351063 borgwarnerspecialist.co.uk

- Longstone Classic & Vintage Car Tyres 01302 711123 longstonetyres.co.uk

- Richards of England 01522 685476 richardsofengland.com

- The Aston Advantage 07595 954882. astonadvantage.uk

OUR VERDICT

The DBS altered the direction for Aston Martin, steering it towards the status of the large high-performance luxury supercars that became increasingly popular throughout the Seventies and beyond. Whether it’s an early six-cylinder or later V8, both off er a level of motoring that was once hard to beat, so if you want a taste of that, a DBS is a worthwhile investment, but choose wisely and ensure you can keep on top of maintenance and repairs.

As Rupert Keyzar of The Aston Advantage says, “Unless the car is being sold through a recognised and reputable Aston Martin specialist, always get a prepurchase inspection first. A shiny body and a clean interior sway many potential buyers, but the majority of problems are always underneath.”

V8 ENGINE

The 5,340cc engine in the DBS V8 consists of an aluminium block and two cylinder heads with a twin overhead camshaft configuration for each. Power output is between 310 and 320bhp, but for the Japanese market, an emissions equipped (EE) V8 produced 250bhp — it had a lower compression ratio of 8.3:1 as opposed to 9:1 and was equipped with an ignition advance/retard system.

Fuelling is provided by a Bosch PES 8KL mechanical injection system and the ignition system uses the Lucas OPUS electronic unit, although the EE engine has a Lucas 35D8 distributor. Paul at Richards of England says the OPUS electronic unit can be problematic, so he often replaces it. As for the fuel injection system, “They can be tricky to set up, and can fall out of balance, especially if the vehicle is not used regularly,” he says. “The Bosch pumps are also a known issue, with only a select few specialists able to rebuild them correctly.”

Darren at ASD comments that, “The injection system is good if set up correctly and not messed around with, but oil changes on the oil bath on the injection pump often get missed and are essential. Also, the pump should never be adjusted with the engine running because this breaks the pump and requires a rebuild which costs in the region of £3,600 on exchange.”

A V8 engine rebuild can cost £25,000- £30,000, and the capacity can be increased to 5.7 litres.